Anti-Glare vs Anti-Reflection: Enhancing Outdoor Readability for IPS Displays

A practical comparison of AG and AR solutions, their cost-performance balance, and how they integrate with high-brightness backlights and optical bonding.

When designing IPS displays for outdoor or high-light environments, two surface treatments are commonly considered: Anti-Glare (AG) and Anti-Reflection (AR). These treatments play a decisive role in determining whether a display can deliver clear, comfortable, and reliable viewing under sunlight, bright indoor lighting, or industrial conditions.

This article explores in detail:

- How each treatment affects contrast and clarity

- The trade-offs in cost, brightness, and color accuracy

- Best practices for combining AG or AR with optical bonding

- Real-world examples from industrial HMI, automotive, and medical devices

Why Outdoor Readability Matters

A display that works perfectly indoors can become almost useless in direct sunlight. The issue is not just brightness — although high-brightness backlights are essential — but also light reflection and glare.

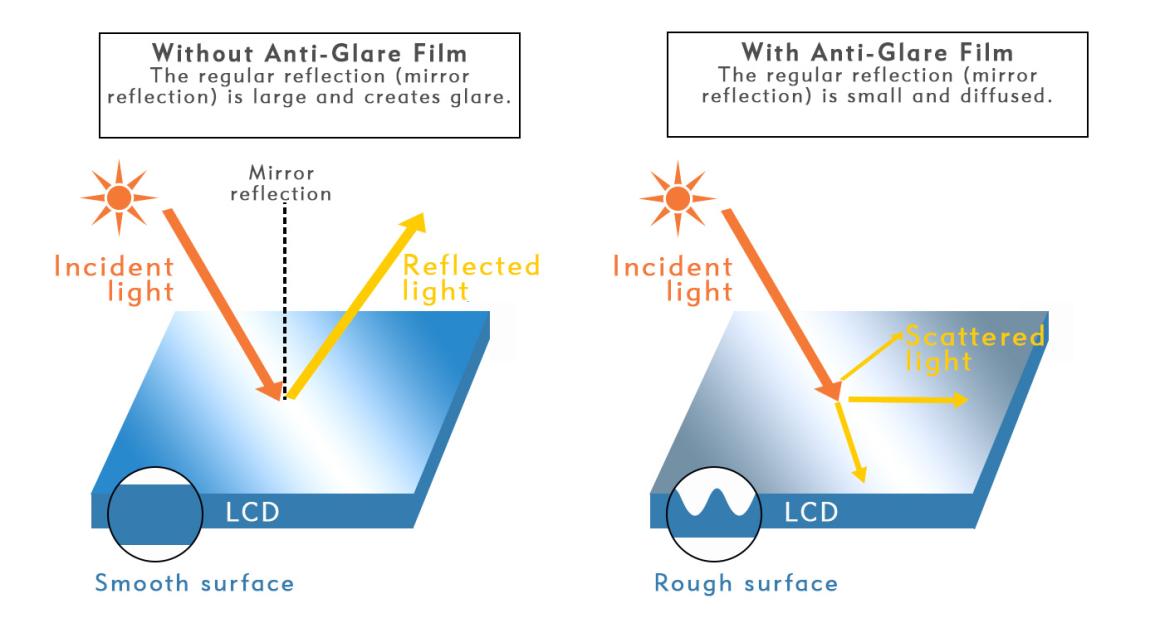

- Reflection happens when external light bounces off the glass surface, creating mirror-like effects that obscure the image.

- Glare diffuses light across the surface, washing out colors and reducing contrast.

Without proper treatment, users are forced to squint, tilt the device, or even shade the screen with their hands. In critical environments such as industrial automation, outdoor kiosks, medical monitoring, or automotive dashboards, poor readability is not just inconvenient — it can be unsafe.

This is where AG and AR solutions step in.

What Is Anti-Glare (AG)?

Anti-Glare (AG) is achieved by etching or applying a micro-rough surface on the top glass layer. This diffuses incoming light, spreading it across multiple directions so that no sharp reflections reach the user’s eyes.

Key Benefits:

- Reduced mirror reflections — improves readability outdoors.

- Wider viewing comfort — less eye strain over long periods.

- Cost-effective — AG coatings are generally cheaper to produce compared to AR.

Limitations:

- Slight image softening — because AG scatters both ambient light and display light, fine text or detailed graphics may appear less sharp.

- Reduced contrast — black levels can look slightly gray under strong sunlight.

AG is therefore widely used in consumer electronics (laptops, tablets) where balanced readability and cost matter more than perfect optical performance.

What Is Anti-Reflection (AR)?

Anti-Reflection (AR) uses thin-film interference coatings applied to the surface of the glass. These coatings minimize reflection by causing destructive interference of incoming light waves.

Key Benefits:

- Superior clarity — AR maintains sharpness, making text and images appear crisp.

- Higher contrast — blacks remain deep, and colors stay vivid even in bright light.

- Premium visual quality — ideal for professional and medical-grade monitors.

Limitations:

- Higher cost — AR coatings require precision deposition processes.

- Fingerprints more visible — smooth AR coatings show smudges more easily.

- Durability concerns — low-quality AR coatings can scratch or peel over time.

AR is favored in automotive displays, surgical monitors, and industrial HMIs where maximum readability is mission-critical.

Comparing AG and AR: Cost vs Performance

| Feature | Anti-Glare (AG) | Anti-Reflection (AR) |

|---|---|---|

| Clarity | Slightly reduced (diffusion) | High clarity (preserves sharpness) |

| Contrast | Moderate | Excellent |

| Cost | Lower | Higher |

| Durability | High (etched surface is stable) | Depends on coating quality |

| Applications | Consumer, office, budget panels | Automotive, medical, industrial |

In short:

- AG = Practical, affordable, “good enough.”

- AR = Premium, high-cost, “best-in-class.”

For many projects, the choice comes down to budget vs performance requirements.

The Role of Optical Bonding

Both AG and AR treatments are often paired with optical bonding — the process of laminating the display cover glass directly to the LCD module using an optically clear adhesive (OCA).

Why Optical Bonding Helps:

- Eliminates the air gap that otherwise causes internal reflections.

- Improves sunlight readability by reducing light scatter.

- Enhances ruggedness by increasing mechanical strength.

- Improves touch accuracy in capacitive touch displays.

For outdoor IPS displays, the most effective combination is often AR + optical bonding, although AG + bonding is still a significant improvement over untreated glass.

Industry Applications

1. Industrial HMI Panels

Factories, oil rigs, and outdoor control stations often require operators to view displays under direct sunlight or bright lamps. In these cases:

- AG is chosen for cost-sensitive applications.

- AR with bonding is used when operators need sharp, precise visuals to avoid errors.

2. Medical Devices

Surgical displays and patient monitors must show critical data with absolute clarity. Even minor glare can cause fatigue or misreading. Therefore, AR-coated IPS panels with bonding are becoming the standard.

3. Automotive Displays

Dashboard clusters, navigation systems, and rear-seat entertainment units all face direct sunlight. Automakers are increasingly adopting AR + bonding to provide drivers with safe, glare-free visibility.

4. Outdoor Kiosks and POS

Self-service kiosks, ATMs, and vending machines use AG when cost is critical, but premium models — especially those installed in airports or transportation hubs — rely on AR solutions.

Choosing Between AG and AR

When deciding which to use, consider:

- Environment — indoor vs outdoor, direct sunlight vs shaded.

- User expectations — consumer devices may tolerate slight softness, but professionals demand precision.

- Budget — AG reduces costs, AR increases them but provides a superior experience.

- Durability — AG surfaces are permanent; AR coatings require higher-quality manufacturing to remain durable.

A practical rule of thumb:

- Use AG if you need affordability and “good-enough” readability.

- Use AR if clarity and precision are mission-critical.

Integrating High-Brightness Backlights

Even with AG or AR coatings, display brightness remains a limiting factor outdoors. IPS panels designed for outdoor use often include:

- High-brightness LED backlights (1000+ nits).

- Enhanced thermal management (to handle increased LED heat).

- Driver circuits optimized for efficiency.

Combining a high-brightness backlight with AR-coated and optically bonded glass produces the best sunlight-readable displays. However, this also raises power consumption and cost, which may not be suitable for all projects.

Future Trends: Hybrid AG/AR Solutions

Manufacturers are now experimenting with hybrid AG/AR coatings that combine the benefits of both:

- Reduced diffuse glare (like AG).

- Maintained sharpness and contrast (like AR).

- Reasonable cost compared to full AR coatings.

These hybrid solutions are expected to become more common in next-generation industrial displays and automotive dashboards.

Conclusion

Both Anti-Glare (AG) and Anti-Reflection (AR) are effective solutions for improving IPS display readability in outdoor environments.

- AG offers a cost-effective balance, suitable for many consumer and mid-range industrial products.

- AR provides unmatched clarity and contrast, essential for mission-critical applications in medical, automotive, and high-end industrial markets.

- Optical bonding further enhances performance by eliminating internal reflections and improving durability.

Ultimately, the right choice depends on budget, performance expectations, and use-case environment.

👉 For further insights into IPS and TFT display technologies, and for curated technical resources, you can check my profile here: Kevin’s GitHub Resources.